我国淡水资源短缺,全国约有1/5的城市严重缺水,为了缓解水资源短缺问题,亟需开发利用非常规水源,减轻用水压力。再生水是人工的第二水源,城市污水再生水就属于第二水源。污水再生利用能够减少对常规水的消耗,不仅能够节约水资源,而且能够减少污水排放给环境水体所带来的污染。这对污水处理行业提出了更高的要求,带来了新的挑战与机遇。为克服传统污水脱氮除磷技术的缺点,多点进水多级AO工艺应运而生。多点进水多级AO工艺是在传统AAO工艺及Bardenpho工艺的基础上结合发展而来,在日本应用较为广泛,最近在我国开始逐步推广使用,其多级AO的级数在2~4级。我国目前应用该工艺的类似案例包括辽宁锦州、天津张贵庄、石家庄桥西等污水处理厂的提标改造工程,均取得了较好的效果。

本文针对北方寒冷地区污水处理厂污水在冬季一般低碳高氮、达标困难的难题,提出了多点进水多级AO工艺的技术特点、影响因素及设计计算方法,可为类似项目的设计计算提供参考。

01 项目概况

1.1 背景

唐山市中心城区规划污水量约为80万m3/d,根据市政府的规划要求,对再生水的处理必须占到集中处理污水的60%以上。唐山市政府在2018年又出台了《全域治水清水润城工程实施方案》,由于原中心城内污水厂对周边环境影响日益受到公众关注,以及排放标准的进一步提高,须将原中心城的污水厂进行迁建,新建2座大型规模的污水厂,出水标准达到“准Ⅳ类”水(除TN外,其余指标均达到地表水Ⅳ类标准),同时可为唐山市提供再生水资源。

唐山市地处渤海湾中心地带,多年年平均气温在10.0~11.3 ℃。1月温度最低,平均温度只有-6.4 ℃,且曾出现-28.2 ℃的极端气温。寒冷地区冬季温度较低,在生物反应阶段,由于污水中的微生物活性以及微生物的生长代谢受到低温的影响,污水厂的脱氮除磷效果明显下降。在活性污泥法处理过程中,大部分微生物属于中温菌,在低温条件下微生物对污染物的吸附、降解性能会下降,极大提高了污染物的去除难度,在深度处理阶段依靠消耗大量药剂和能源进行处理,以满足现行的排放标准。若采用常规工艺,将消耗更多的资源和能源,能耗过大。因此,针对唐山当地污水水质的特点采用多点进水多级AO生物处理工艺进行处理,可显著节约碳源,实现污水节能降耗精准治理和再生。

1.2 水质分析

1.2.1 现状水质分析

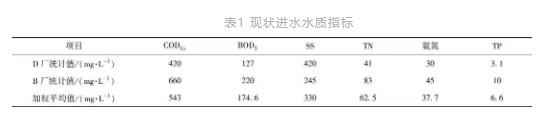

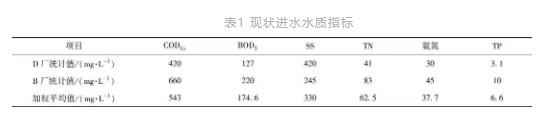

(1)进水水质实测统计分析

对现状污水厂2016年1月—2018年11月每天的进水化学需氧量(COD)、生化需氧量(BOD5)、悬浮物(SS)、氨氮、总氮(TN)、总磷(TP)实验室实测水质指标进行统计分析,按85%或以上保证率的水质浓度作基本依据进行确定的进水水质如表1所示。

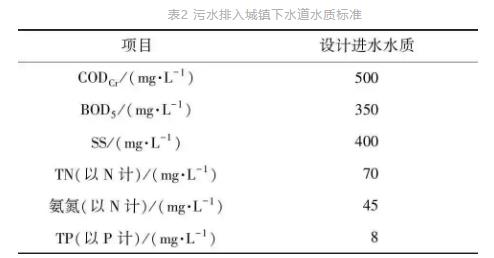

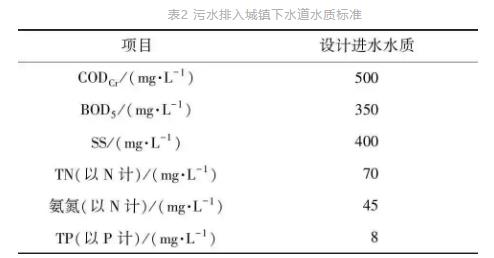

实际进水水质一般都会与原设计的水质有一定程度的差异,本工程设计进水水质主要需按照实测水质统计值进行确定。由于D厂和B厂现状进水量和设计污水量均基本相同,按照二者进水水质加权平均值作为本工程进水水质参考值。(2)按《污水排入城镇下水道水质标准》复核进水水质在《污水排入城镇下水道水质标准》(GB/T 31962—2015)中,对排入城市下水道的工业废水有明确的水质指标规定,主要水质指标如表2所示。

本工程中,实际进水水质不能超过《污水排入城镇下水道水质标准》(GB/T 31962—2015)的水质指标要求,因此,将进水水质的标准设计为CODCr≤500 mg/L。

(3)远期纳管水质构成分析

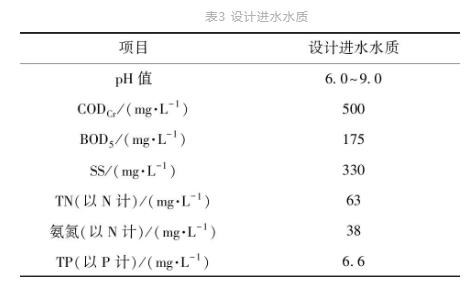

根据规划,本工程远期进水中工业污水所占比例会越来越低,生活污水比例逐步提高。目前,进水BOD5较低,远期随着生活污水比例上升,BOD5将有所提高,污水BOD5/CODCr会提高,可生化性相应提高,将有利于水处理的效果提升,因此,BOD5按实测统计值(175 mg/L)设计。按上述进水水质作为设计依据可以满足远期需求。同时在近期污水厂工艺设计时,也会考虑近期短历时高浓度进水影响因素,选择合适的处理工艺。

(4)设计进水水质的最终确定

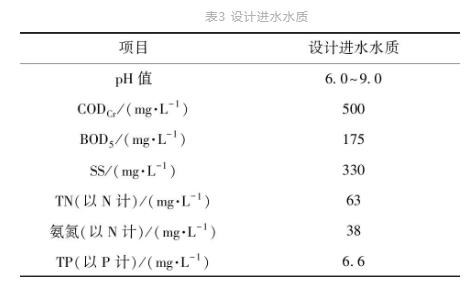

通过上述分析,本工程进水水质如表3所示。

(5)污水性质分析

本工程中,进水水质设定为TN质量浓度为63 mg/L;BOD5质量浓度为175 mg/L,BOD5/TN=2.78,而一般认定污水中碳源充足的标准为BOD5/TN≥3,同时计算结果显示,进水水质中的碳源达不到反硝化菌的供应要求,因此,需补充碳源。为节约碳源和运行费用,本工程需采用适应低碳高氮污水的节碳工艺。

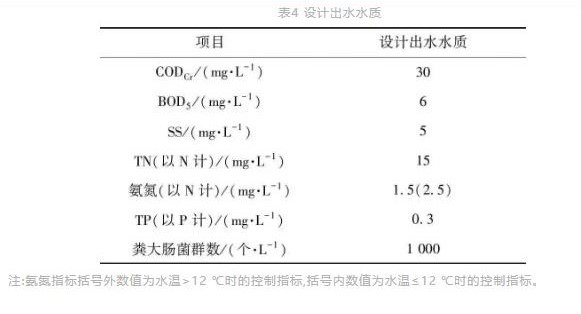

1.2.2 设计出水水质

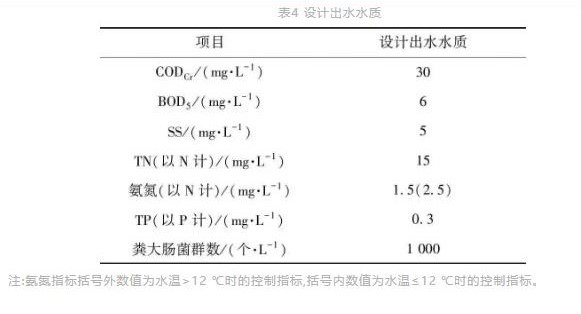

本工程中,经处理后的废水,出水指标达到北京地标《城镇污水处理厂污染物排放标准》(DB 11/890—2012)中B标准的要求,主要水质指标符合Ⅳ类水体标准的要求,具体要求如表4所示。

02 多点进水多级AO工艺

2.1 工艺概况

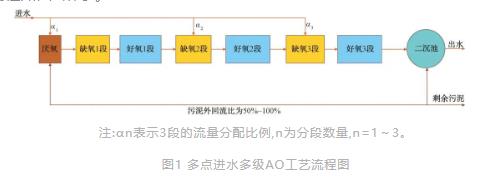

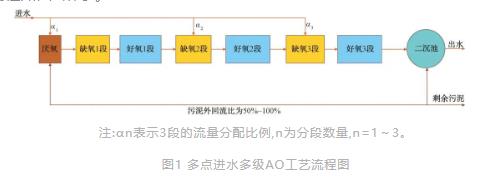

多点进水多级AO在流程上与改良Bardenpho工艺相类似,但AO段根据脱氮需求,增加至3段,并通过精确的分点进水,有效分配碳源。多段AO按照缺氧/好氧安排系统结构,此环境下,反硝化菌以及硝化菌能够更好地生长。通过交替性布置,使得进水的有机碳源,在各段中都能够进行充分地反硝化,保证最后的出水TN浓度达到标准要求,从而为深度脱氮提供良好的基础。如果能够确保最后一段有足够小的进水量,或在最后一段适量投加一定的碳源,可保证出水TN质量浓度<1 mg/L。本工程通过交替性布置,使得缺氧/好氧无需增加内循环系统就可以实现,不仅有利于降低项目投资,而且系统运行能耗有效下降。这一设计手法有效解决了AO的高效运行难题。多点进水多级AO工艺流程如图1所示。

2.2 工艺特点

多点进水多级AO工艺的形式使其具有以下优点。

(1)交替布置使得缺氧/好氧无需增加内循环系统就可以实现,不仅不需要增加硝化液回流设施来促进内循环,而且还能充分发挥水质中碳源的作用,让反硝化更为充分并持续进行,在低C/N的污水中能够实现效果非常好的高效脱氮。

(2)各段中的污水通过分散进入的方式,来推迟总稀释作用的发生,使得各段中水体的污泥浓度(MLSS)形成梯度式的分布。相比其他的脱氮工艺,如果二沉池具有同样的MLSS,假设不增加二沉池负荷,多点进水多级AO工艺的MLSS更高,固体物的停留时间也会更长。多点进水多级AO工艺还可以通过合理设置进水点与进水流量分配比,来提高系统的MLSS平均水平,一般可以提高35%~70%,不仅单位池容处理能力得到有效提升,而且脱氮所需池容也大大减少。

(3)缺氧区进水中的有机物可作为反硝化所需的碳源,反硝化菌充分利用原生污水中易生物降解的CODCr,从而达到节省投加外部碳源的目的;缺氧区进水中可利用碳源在反硝化过程中消耗非常大,后续好氧区可利用的碳源因此大大减少,可以抑制异养菌的生长,为自养硝化菌创造更有利的生长环境。

(4)缺氧区在布置时与好氧区形成交替形式,缺氧区产生的碱度可以用来补充好氧区的碱度,使得系统的碱度能够维持相对的平衡;缺氧区与好氧区交替布置的形式使得每段的缺氧区成为高负荷选择器,对丝状菌的污泥膨胀形成良好的抑制作用。

(5)生反池中的污水,通过分散进入方式,能够有效增强系统的抗冲击负荷力。如果是合流制排水系统或者有雨污混接的分流制系统,只需调整流量分配比,就可有效避免暴雨所产生的巨大洪峰流量对污泥的冲刷损失。2.3影响因素

影响多点进水多级AO工艺处理效率的因素主要包括污泥龄、混合液回流、进水分配比、缺氧/好氧可调容积比、反应器段数、温度、BOD5污泥负荷等。03多点进水多级AO工艺工程设计

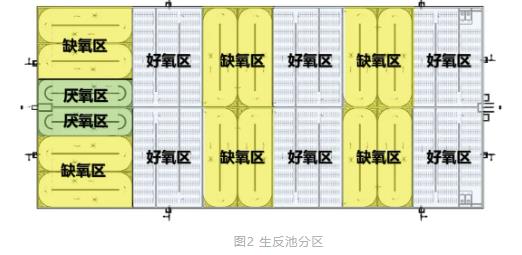

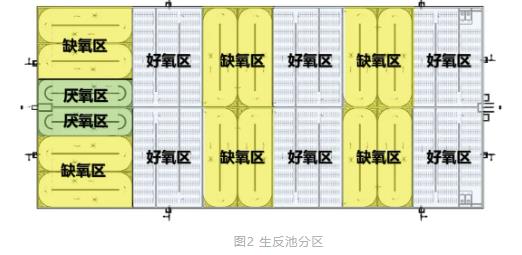

本工程近期共设置3座多点进水多级AO生物反应池,单座规模为10万m3/d,每座设厌氧段、一段AO、二段AO、三段AO。每池空气管形成支状,并设有电动调节阀,可通过电动调节阀对好氧池内溶解氧(DO)进行控制,对生物脱氮以及节能都有较好的效果。生反池分段分区如图2所示。

缺氧与好氧交替布置的形式使得原水中的碳源得到充分利用,从而让污水在各段中完全完成反硝化反应,因此,最后一段AO池的污水进水量决定了生反池的出水TN浓度,这种缺氧与好氧的交替布置能实现深度脱氮的目的。AO池数量为3座,每座分2组,每组可独立运行,每组处理能力为5万m3/d,有效水深为7.0 m。多点进水多级AO工艺工程设计方法主要参考《废水工程:处理及回用》(第4版)。

(1)分段数量n

等比例进水情况下,各段的脱氮效率计算如式(1)。

其中:η——脱氮效率;

n——分段数量;

r——污泥回流比,取100%。

实际脱氮效率η计算如式(2)。

η=(1-Ne/N0)×100% (2)

其中:N0——进水TN质量浓度,mg/L;

Ne——出水TN质量浓度,mg/L。

本工程实际脱氮效率η=(1-Ne/N0)×100%=(1-15/63)×100%=76%。

根据式(1),n=1/(1-76%)/(1+100%)=2.1,为保证脱氮效果,取分段数n=3。

(2)流量分配比例αn

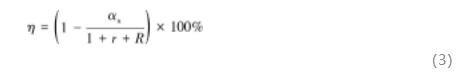

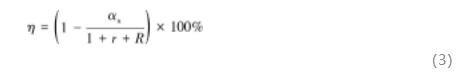

采用变比例进水,假设前一段硝化产生的在随后的缺氧段完全反硝化,则工艺最后出水的含量仅与末端进水比例有关,变比例进水脱氮效率如式(3)。

其中:αn——最后一段进水比例;

R——系统最后一段的内回流比,取100%。

由于实际脱氮效率为76%,校核变比例进水计算的脱氮效率需大于此数值。

当第一缺氧段完成对硝氮的反硝化,且第一段进水中的BOD5全部用于反硝化时,则式(4)成立。

其中:k——反硝化单位所需要的有机物的量,取图片

Nc——出水硝氮质量浓度,mg/L;

S0——进水BOD5质量浓度,mg/L。

可利用此公式校核第一缺氧段进水中反硝化需要的碳源是否充足。

流量分配比例的两种设计计算方法如下。

(a)等负荷流量分配法:保持各段好养区硝化菌的污泥负荷相等(假定各段AO容积相同),如式(5)和式(6)。

求解得到α1=39.8%;α2=32.4%;α3=28.1%。

采用式(7)复核缺氧池反硝化所需碳源是否充足。

αi/αi-1=k×Nk/S0 (7)

其中,Nk——进水凯氏氮(TKN)质量浓度,mg/L。

本工程k×Nk/S0=3×59.85/149=1.21,缺氧池碳源不足,无法采用等负荷流量分配法。

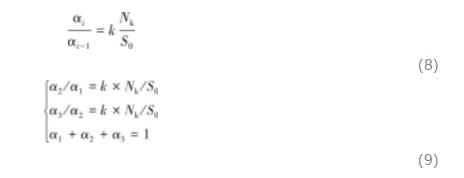

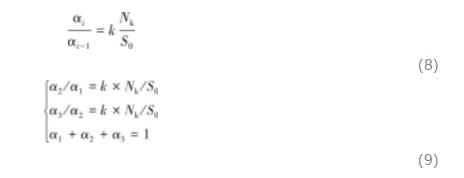

(b)流量分配系数法,如式(8)和式(9)。

求解得到α1=25.79%;α2=32.71%;α3=41.50%。

校核缺氧1段碳源:

α1=25.79%>kr(Nc/S0)=3×100%×(10.5/149)=21%,碳源充足。

校核脱氮效率:

η=[1-41.50%/(1+100%+100%)]×100%=86.2%>75%,可实现出水TN质量浓度<15 mg/L。

冬季时硝化反应受低温限制,应适当延长硝化时间,可通过调整减少最后1~2级的进水量,以此来弥补低温带来的影响。

(3)好氧段泥龄θco,计算如式(10)。

其中:θco——好氧段泥龄,d。

F——安全系数,取3;

Na——生反池中氨氮质量浓度,mg/L;

Kn——硝化作用中氮的半速率常数,一般取1 mg/L,mg/L;

T——设计最低水温,取12 ℃,℃。

计算得到:

θco=3×1/[0.47×1.5/(1+1.5)×e0.098×(12-15)]=14.3 d,取θco=14.3 d。

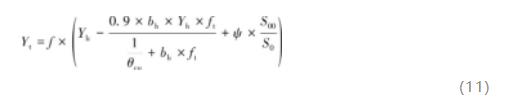

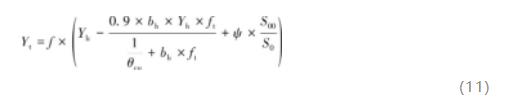

(4)污泥总产率系数Yt,计算如式(11)。

其中:Yt——污泥总产率系数;

f——污泥产率修正系数,取0.85;

Yh——异养菌产率系数,取0.6 kg SS/(kg BOD5);

bh——异养菌内源衰减系数,取0.08 d-1,d-1;

ft——温度修正系数,为1.072(T-15);

ψ——进水中不可降解SS与总SS比例,取0.5;

S00——进水SS质量浓度,mg/L。

计算得到:

Yt=0.85×[0.6-(0.9×0.08×0.6×1.07212-15)/(1/14.3+0.08×1.07212-15)+0.5×165/149]=0.76 kg SS/(kg BOD5)。

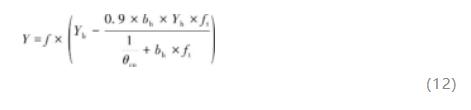

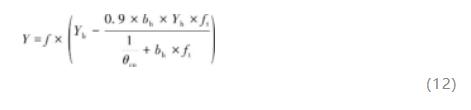

(5)污泥净产率系数Y,计算如式(12)。

求解得到:

Y=0.85×[0.6-(0.9×0.08×0.6×1.07212-15)/(1/14.3+0.08×1.07212-15)]=0.29 kg VSS/(kg BOD5)。

(6)每段AO容积比VA∶VO,计算如式(13)。

其中:Q——生反池进水量,万m3/d;

SMLSS——污泥质量浓度,mg/L;

Se——出水BOD5质量浓度,mg/L;

Rn——剩余污泥含氮率,取12%;

kde——20 ℃时脱氮速率,取0.05kg NO3--N/(kg MLSS·d)

将相关参数带入,得到VA∶VO=0.61∶1。

每段AO容积比相同,亦可根据每段去除TN及BOD5量,优化每段AO采用不同的容积比。

(7)总泥龄θc、好氧段泥龄θco、缺氧段泥龄θcd之间的关系如式(14)和式(15)。

θcd∶θco=VA∶VO (14)

θc=θcd+θco (15)

其中:θc——总泥龄,d;

θcd——缺氧段泥龄,d。

计算得:

θcd∶θco=VA∶VO=0.61;

θc=θcd+θco=14.3×1.61=23.0 d。

(8)回流污泥浓度Xr,计算如式(16)。

其中:tE——二沉池浓缩时间,取2 h,h。

RSVI——污泥容积指数,取125。

图片 取7 g/L。

(9)反应池内污泥浓度Xi,计算如式(17)。

其中:Xi——反应池内污泥质量浓度,g/L。

求解得到:

X1=7×100%/(100%+25%)=5.6 g/L;

X2=7×100%/(100%+35%+25%)=4.4 g/L;

X3=7×100%/(100%+1)=3.5 g/L。

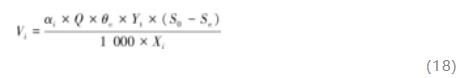

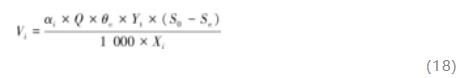

(10)每段AO池容Vi,计算如式(18)。

其中:Vi——每段AO池容,m3。

经复核,各段AO停留时间分别为T1=2.68 h,T2=4.77 h,T3=6.85 h,设计取值分别为T1=3.0 h,T2=5.0 h,T3=7.0 h。

(11)单组生反池设计参数汇总如下。

本工程单组生反池处理规模为5m3/d,设计最低水温为12 ℃,最高水温为25 ℃。

经计算,产泥率为0.76 kg DS/(kg BOD5),好氧区污泥负荷为0.12 kg BOD5/(kg MLSS·d),系统泥龄为23.0 d,好氧泥龄为14.3 d。

停留时间方面,厌氧停留时间为1.0 h,多段AO区停留时间为15 h,总停留时间为16 h,其中各段AO停留时间比例为3∶5∶7,每段AO停留时间比例为0.61∶1,缺氧区总停留时间为5.7 h,好氧区总停留时间为9.3 h。

进水分配比例采用2.5∶3.5∶4.0,设计水深为7.0 m,外回流污泥为50%~100%。

曝气系统总的气水比为6.3∶1,各段好氧区曝气量比例为1.0∶1.6∶2.0,采用曝气管,通过精确曝气系统进行控制。

(12)后续深度处理工艺段

本工程后续污水深度处理工艺方案为“高效沉淀池+深床滤池”工艺,以进一步去除生反池出水中的SS和TP。同时在末端设置了O3催化氧化系统,当出水CODCr不达标时,启用该系统投加O3进行强化处理,确保出水达标,在平时能达标时则不开启O3催化氧化系统。

04 效益分析

多点进水多级AO工艺无需内回流,根据内回流污泥泵的功率计算,与常规100%内回流相比,多点进水多级AO工艺按30万m3/d的污水处理规模计算,全年可节约用电228万kW·h,约占全厂用电量的2%,按0.573元/(kW·h)电核算,可每年节约运行成本约为131万元。

多点进水多级AO工艺无需额外补充碳源,按30万m3/d的污水处理规模计算,每天可节约33%浓度的乙酸钠溶液约为18 m3,按乙酸钠3 000元/m3计算,全年可节约运行费用约为1 944万元。

05 结语

(1)多点进水多级AO工艺交替布置缺氧和好氧段,使得无需增加内循环系统就可以实现脱氮,节约能源。

(2)多点进水多级AO工艺在寒冷地区低碳高氮污水处理中有比较明显的优势,其可优化分配污水中的碳源,使得碳源能够精准地被用于脱氮除磷,节约碳源。

(3)多点进水多级AO工艺节能降耗,节约碳源,是新时代碳达峰碳中和背景下值得广泛推广的技术。

China's fresh water resources are short, about 1/5 of the country's cities are seriously short of water, in order to alleviate the problem of water shortage, it is urgent to develop and use unconventional water sources to reduce water pressure. Reclaimed water is the second artificial water source, and urban sewage reclaimed water belongs to the second water source. Sewage recycling can reduce the consumption of conventional water, not only save water resources, but also reduce the pollution caused by sewage discharge into environmental water bodies. This puts forward higher requirements for the sewage treatment industry and brings new challenges and opportunities. In order to overcome the shortcomings of traditional sewage nitrogen and phosphorus removal technology, the multi-point influent multi-stage AO process came into being. Multi-point influent multi-stage AO process is developed on the basis of traditional AAO process and Bardenpho process, widely used in Japan, recently began to gradually promote and use in China, its multi-level AO stage in 2~4 level. Similar cases of the application of this process in China include the upgrading and transformation projects of sewage treatment plants such as Jinzhou in Liaoning, Zhangguizhuang in Tianjin, and Qiaoxi in Shijiazhuang, all of which have achieved good results.

In view of the problem that sewage from sewage treatment plants in northern cold areas is generally low-carbon, high nitrogen and difficult to meet standards in winter, this paper puts forward the technical characteristics, influencing factors and design calculation methods of multi-point influent multi-stage AO process, which can provide reference for the design and calculation of similar projects.

01 Project Overview

1.1 Background

The planned sewage capacity of the downtown area of Tangshan is about 80,<> m3/d, according to the planning requirements of the municipal government, the treatment of reclaimed water must account for more than 60% of the centralized treatment of sewage. In 2018, the Tangshan Municipal Government issued the "Implementation Plan for the Global Water Control and Clean Water and Water Run City Project", due to the increasing public attention to the environmental impact of the original sewage plant in the central city, and the further improvement of discharge standards, it is necessary to relocate the sewage plant in the original central city and build two large-scale sewage plants, and the effluent standard reaches "quasi-class IV." water (except TN, the other indicators reach the surface water class IV standard), and at the same time can provide renewable water resources for Tangshan City.

Tangshan City is located in the center of Bohai Bay, and the annual average temperature is 10.0~11.3 °C for many years. January was the lowest, with an average temperature of -1.6 °C and a temperature extremes of -4.28 °C. In the cold region, the winter temperature is low, and in the biological reaction stage, due to the microbial activity in the sewage and the growth and metabolism of microorganisms affected by low temperature, the nitrogen and phosphorus removal effect of the sewage plant is significantly reduced. In the process of activated sludge treatment, most of the microorganisms belong to medium temperature bacteria, and the adsorption and degradation performance of microorganisms on pollutants will decrease under low temperature conditions, which greatly improves the difficulty of removing pollutants, and relies on consuming a lot of chemicals and energy in the advanced treatment stage to meet the current emission standards. If conventional processes are used, more resources and energy will be consumed, and the energy consumption will be too large. Therefore, according to the characteristics of local sewage quality in Tangshan, multi-point influent multi-stage AO biological treatment process is adopted, which can significantly save carbon sources and realize precise treatment and regeneration of sewage energy saving and consumption reduction.

1.2 Water quality analysis

1.2.1 Current water quality analysis

(1) Statistical analysis of influent water quality

The daily chemical oxygen demand (COD), biochemical oxygen demand (BOD2016), suspended solids (SS), ammonia nitrogen, total nitrogen (TN) and total phosphorus (TP) laboratory of the current sewage plant from January 1 to November 2018 were statistically analyzed, and the water quality of the influent water was determined based on the water quality concentration of 11% or more as the basic basis, as shown in Table 5.

The actual influent water quality will generally be different from the original design water quality to a certain extent, and the influent water quality of this engineering design mainly needs to be determined according to the measured water quality statistical value. Since the current water intake and design sewage volume of Plant D and Plant B are basically the same, the weighted average of the influent water quality of the two is used as the reference value of the influent water quality of this project. (2) Review the influent water quality according to the "Sewage Discharged into Urban Sewer Water Quality Standard" In the "Sewage Discharged into Urban Sewer Water Quality Standard" (GB/T 31962-2015), there are clear water quality index provisions for industrial wastewater discharged into urban sewers, and the main water quality indicators are shown in Table 2.

In this project, the actual influent water quality cannot exceed the water quality index requirements of the "Sewage Discharged into Urban Sewerage Water Quality Standard" (GB/T 31962-2015), so the standard of influent water quality is designed as CODCr≤500 mg/L.

(3) Long-term water quality composition analysis

According to the plan, the proportion of industrial sewage in the long-term influent water of this project will become lower and lower, and the proportion of domestic sewage will gradually increase. At present, the BOD5 of the influent water is low, and in the long term, with the increase of the proportion of domestic sewage, BOD5 will be improved, the BOD5/CODCr of sewage will be improved, and the biochemistry will be correspondingly improved, which will be conducive to the improvement of the effect of water treatment, therefore, BOD5 is designed according to the measured statistical value (175 mg/L). According to the above influent water quality as the design basis, it can meet the long-term demand. At the same time, in the recent process design of the sewage plant, the factors influencing the recent short-duration high-concentration influent water will also be considered, and the appropriate treatment process will be selected.

(4) Final determination of design influent water quality

Through the above analysis, the influent water quality of this project is shown in Table 3.

(5) Analysis of sewage properties

In this project, the influent water quality is set to TN mass concentration of 63 mg/L; The mass concentration of BOD5 was 175 mg/L, BOD5/TN=2.78, and the standard for determining that the carbon source in sewage was sufficient was BOD5/TN≥3, and the calculation results showed that the carbon source in the influent water quality could not meet the supply requirements of denitrifying bacteria, so the carbon source needed to be supplemented. In order to save carbon sources and operating costs, this project needs to adopt a carbon-saving process suitable for low-carbon and high-nitrogen sewage.

1.2.2 Design effluent quality

In this project, the effluent index of the treated wastewater meets the requirements of standard B in the Beijing landmark "Urban Sewage Treatment Plant Pollutant Discharge Standard" (DB 11/890-2012), and the main water quality indicators meet the requirements of Class IV. water body standard, the specific requirements are shown in Table 4.

02 Multi-stage AO process with multi-point water influte

2.1 Process overview

The multi-stage AO of multi-point influent water is similar to the modified Bardenpho process in terms of process, but the AO stage is increased to 3 stages according to the nitrogen removal demand, and the carbon source is efficiently distributed through precise fractional feed. Multi-stage AO according to the hypoxia/aerobic arrangement system structure, in this environment, denitrifying bacteria and nitrifying bacteria can grow better. Through the alternating arrangement, the organic carbon source of the influent water can be fully denitrified in each section to ensure that the TN concentration of the final effluent meets the standard requirements, thus providing a good foundation for deep denitrification. If it can be ensured that the last section has a small enough intake, or a certain amount of carbon source is added to the last section, the mass concentration of TN in the effluent can be guaranteed to be < 1 mg/L. Through the alternating arrangement, this project can be realized without adding the internal circulation system, which is not only conducive to reducing the project investment, but also effectively reducing the energy consumption of the system operation. This design method effectively solves the problem of efficient operation of AO. The multi-stage AO process flow of multi-point influent is shown in Figure 1.

2.2 Process characteristics

The form of multi-point influent multi-stage AO process makes it have the following advantages.

(1) Alternately arranged, so that hypoxia/aerobic can be realized without increasing the internal circulation system, not only does not need to increase nitrification liquid reflux facilities to promote internal circulation, but also can give full play to the role of carbon source in water quality, so that denitrification is more complete and continuous, and very effective and efficient nitrogen removal can be achieved in low C/N sewage.

(2) The sewage in each section delays the occurrence of total dilution by dispersing the inflow, so that the sludge concentration (MLSS) of the water body in each section forms a gradient distribution. Compared with other denitrification processes, if the secondary sedimentation tank has the same MLSS, assuming that the load of the secondary sedimentation tank is not increased, the MLSS of the multi-point influent multi-stage AO process is higher, and the residence time of the solid will be longer. The multi-point inlet multi-stage AO process can also improve the average MLSS of the system by reasonably setting the inlet point and inlet flow distribution ratio, which can generally be increased by 35%~70%, not only the unit pool capacity treatment capacity is effectively improved, but also the pool capacity required for denitrification is greatly reduced.

(3) The organic matter in the influent water in the hypoxic area can be used as the carbon source required for denitrification, and the denitrifying bacteria make full use of the easily biodegradable CODCr in the primary sewage, so as to achieve the purpose of saving the addition of external carbon sources; The carbon source available in the influent water of the hypoxic area is very large in the denitrification process, and the carbon source available in the subsequent aerobic zone is greatly reduced, which can inhibit the growth of heterotrophic bacteria and create a more favorable growth environment for autotrophic nitrifying bacteria.

(4) The hypoxic zone is arranged in an alternating form with the aerobic zone, and the alkalinity generated by the hypoxic zone can be used to supplement the alkalinity of the aerobic zone, so that the alkalinity of the system can maintain a relative balance; The form of alternating arrangement of hypoxic zone and aerobic zone makes the hypoxic zone of each section a high-load selector, which forms a good inhibitory effect on the sludge expansion of filamentous bacteria.

(5) The sewage in the reversing pond can effectively enhance the impact load resistance of the system through the dispersion ingress. If it is a combined drainage system or a diversion system with rain and sewage mixing, only the flow distribution ratio needs to be adjusted, which can effectively avoid the erosion loss of sludge caused by the huge peak flow generated by heavy rain. 2.3 Influencing factors

The factors affecting the efficiency of multi-stage AO process in multi-point influent mainly include sludge age, mixed liquid reflux, influent water distribution ratio, oxygen-deficient/aerobic adjustable volume ratio, reactor stage number, temperature, BOD5 sludge load, etc. 03Multi-point water inlet multi-stage AO process engineering design

Recently, a total of 3 multi-point influent multi-stage AO bioreaction tanks have been set up in this project, with a single scale of 10,<> m3/d, each seat is equipped with anaerobic segment, one AO, two AO, three AO. Each pool of air pipes forms a branch, and is equipped with an electric control valve, which can control the dissolved oxygen (DO) in the aerobic pool through the electric control valve, which has a good effect on biological denitrification and energy saving. Figure 2 shows the fragmented partition of the pool backstage.

The form of alternating arrangement of hypoxia and aerobic makes full use of the carbon source in the raw water, so that the sewage completely completes the denitrification reaction in each section, therefore, the sewage influent of the last section of the AO tank determines the TN concentration of the effluent of the reflux pool, and this alternating arrangement of hypoxic and aerobic can achieve the purpose of deep denitrification. The number of AO pools is 3, each divided into 2 groups, each group can operate independently, each group has a processing capacity of 5,3 m7/d, and the effective water depth is 0.4 m. The engineering design method of multi-stage AO process of multi-point influent water mainly refers to "Wastewater Engineering: Treatment and Reuse" (<>th edition).

(1) The number of subparagraphs n

In the case of equal proportion of water intake, the denitrification efficiency of each section is calculated as shown in Equation (1).

Among them: η - nitrogen removal efficiency;

n - number of segments;

r - sludge reflux ratio, take 100%.

The actual denitrification efficiency η calculated as in Equation (2).

η=(1-Ne/N0)×100% (2)

Among them: N0 - mass concentration of TN in influent water, mg/L;

Ne - effluent TN mass concentration, mg/L.

The actual denitrification efficiency of this project η=(1-Ne/N0)×100%=(1-15/63)×100%=76%.

According to equation (1), n=1/(1-76%)/(1+100%)=2.1, in order to ensure the nitrogen removal effect, take the number of segments n=3.

(2) Flow distribution ratio αn

Using variable proportion influent, assuming that the previous stage of nitrification is completely denitrified in the subsequent hypoxic section, the content of the final effluent of the process is only related to the proportion of the terminal influent, and the efficiency of the variable proportion influent water is as shown in Equation (3).

Among them: αn - the proportion of water inlet in the last section;

R - the internal reflux ratio of the last section of the system, whichever is 100%.

Since the actual nitrogen removal efficiency is 76%, the nitrogen removal efficiency calculated by checking the variable proportion of the influent water needs to be greater than this value.

Equation (5) is true when the denitrification of nitrate is completed in the first hypoxic section, and all the BOD4 in the first stage of the feed water is used for denitrification.

Among them: k - the amount of organic matter required by the denitrification unit, take the picture

Nc - mass concentration of nitrate nitrogen in effluent, mg/L;

S0 - influent BOD5 mass concentration, mg/L.

This formula can be used to check whether the carbon source required for denitrification in the first anoxic section of the influent water is sufficient.

The two design calculation methods for the traffic distribution ratio are as follows.

(a) Equal load flow distribution method: keep the sludge load of nitrifying bacteria in each section of the good culture area equal (assuming that the AO volume of each section is the same), such as Equation (5) and Equation (6).

The solution yields α1=39.8%; α2=32.4%; α3=28.1%。

Formula (7) is used to review whether the carbon sources required for denitrification of the hypoxic pond are sufficient.

αi/αi-1=k×Nk/S0 (7)

Among them, Nk - the mass concentration of Kjeldahl nitrogen (TKN) in the influent water, mg/L.

In this project, k×Nk/S0=3×59.85/149=1.21, the carbon source of the hypoxic pool is insufficient, and the equal load flow distribution method cannot be used.

(b) Flow distribution coefficient method, such as Equations (8) and (9).

The solution yields α1=25.79%; α2=32.71%; α3=41.50%。

Check the carbon source of hypoxia stage 1:

α1=25.79%>kr(Nc/S0)=3×100%×(10.5/149)=21%, sufficient carbon source.

Check the nitrogen removal efficiency:

η=[1-41.50%/(1+100%+100%)]×100%=86.2%>75%, the mass concentration of TN in the effluent can be < 15 mg/L.

In winter, the nitrification reaction is limited by low temperature, and the nitrification time should be appropriately extended, and the water intake of the last 1~2 stage can be reduced by adjusting to make up for the impact of low temperature.

(3) The aerobic section mud age θco, calculated as in equation (10).

Among them: θco - aerobic segment mud age, d.

F - safety factor, take 3;

Na - mass concentration of ammonia nitrogen in the reflux pool, mg/L;

Kn - the half-rate constant of nitrogen in nitrification, generally 1 mg/L, mg/L;

T - design the minimum water temperature, take 12 °C, °C.

The calculation yields:

θco=3×1/[0.47×1.5/(1+1.5)×e0.098×(12-15)]=14.3 d,取θco=14.3 d。

(4) The total sludge yield coefficient Yt, calculated as in equation (11).

Among them: Yt - total sludge yield coefficient;

f - sludge yield correction coefficient, take 0.85;

Yh - heterotrophic yield coefficient, take 0.6 kg SS/(kg BOD5);

bh - endogenous attenuation coefficient of heterotrophic bacteria, take 0.08 d-1, d-1;

ft - temperature correction coefficient, 1.072 (T-15);

ψ - the ratio of non-degradable SS to total SS in the influent water, take 0.5;

S00 - mass concentration of SS in influent water, mg/L.

The calculation yields:

Yt=0.85×[0.6-(0.9×0.08×0.6×1.07212-15)/(1/14.3+0.08×1.07212-15)+0.5×165/149]=0.76 kg SS/(kg BOD5)。

(5) The net yield coefficient of sludge is Y, calculated as in equation (12).

The solution yields:

Y=0.85×[0.6-(0.9×0.08×0.6×1.07212-15)/(1/14.3+0.08×1.07212-15)]=0.29 kg VSS/(kg BOD5)。

(6) The AO volume ratio of each segment is VA∶VO, calculated as in equation (13).

Among them: Q - water influence of the rebel pond, 3,<> m<>/d;

SMLSS – sludge mass concentration, mg/L;

Se - effluent BOD5 mass concentration, mg/L;

Rn - nitrogen content of remaining sludge, take 12%;

kde——denitrification rate at 20 °C, take 0.05kg NO3--N/(kg MLSS·d)

Bring in the relevant parameters to get VA∶VO=0.61∶1.

The volume ratio of each AO is the same, and different volume ratios can be optimized for each segment AO according to the removal of TN and BOD5 in each segment.

(7) The relationship between total mud age θc, aerobic segment mud age θco, and hypoxic segment mud age θcd is as shown in Equations (14) and (15).

θcd∶θco=VA∶VO (14)

Θc=Θcd+Θco (15)

where: θc - total mud age, d;

θcd – mud age in the hypoxic segment, d.

Calculated as:

θcd∶θco=VA∶VO=0.61;

Θc=Θcd+Θco=14.3×1.61=23.0 d。

(8) The concentration of reflux sludge Xr, calculated as in equation (16).

Among them: tE - the concentration time of the second sedimentation tank, take 2 h, h.

RSVI - sludge volume index, take 125.

Image 7 g/L.

(9) The concentration of sludge in the reaction tank Xi is calculated as in Equation (17).

Among them: Xi - the mass concentration of sludge in the reaction tank, g/L.

The solution yields:

X1=7×100%/(100%+25%)=5.6 g/L;

X2=7×100%/(100%+35%+25%)=4.4 g/L;

X3=7×100%/(100%+1)=3.5 g/L。

(10) The AO pool capacity Vi of each segment is calculated as in Equation (18).

Where: Vi - each segment of AO pool capacity, m3。

After review, the AO residence time of each segment was T1=2.68 h, T2=4.77 h, T3=6.85 h, and the design values were T1=3.0 h, T2=5.0 h, and T3=7.0 h, respectively.

(11) The design parameters of a single group of reversing pools are summarized as follows.

The treatment scale of the single-group reversing tank in this project is 5m3/d, and the minimum water temperature is 12 °C and the maximum water temperature is 25 °C.

The sludge yield was calculated to be 0.76 kg DS/(kg BOD5), the sludge load in the aerobic zone was 0.12 kg BOD5/(kg MLSS·d), the system sludge age was 23.0 d, and the aerobic sludge age was 14.3 d.

In terms of residence time, the anaerobic residence time was 1.0 h, the residence time of multiple AO zones was 15 h, and the total residence time was 16 h, of which the ratio of AO residence time in each segment was 3:5∶7, the proportion of AO residence time in each segment was 0.61:1, the total residence time in the hypoxic zone was 5.7 h, and the total residence time in the aerobic zone was 9.3 h.

The influent distribution ratio adopts 2.5:3.5:4.0, the design water depth is 7.0 m, and the external return sludge is 50%~100%.

The total air-water ratio of the aeration system is 6.3:1, and the aeration ratio of aerobic zone in each section is 1.0:1.6:2.0, which is controlled by the precision aeration system by using an aeration tube.

(12) Subsequent advanced treatment process section

The follow-up sewage advanced treatment process scheme of this project is the "high-efficiency sedimentation tank + deep bed filter tank" process to further remove SS and TP in the effluent of the rebel tank. At the same time, an O3 catalytic oxidation system is set at the end, and when the effluent CODCr does not meet the standard, the system is enabled to add O3 for intensive treatment to ensure that the effluent meets the standard, and the O3 catalytic oxidation system is not turned on when the standard can be reached at ordinary times.

04 Benefit analysis

Multi-point inlet multi-stage AO process does not need internal reflux, according to the power calculation of the internal return sludge pump, compared with the conventional 100% internal reflux, the multi-point influent multi-stage AO process is calculated according to the scale of 30,3 m228/d sewage treatment, which can save 2.0 million kW·h of electricity consumption throughout the year, accounting for about 573% of the electricity consumption of the whole plant, and save about 131.<> million yuan in operating costs per year according to <>.<> yuan / (kW·h) electricity accounting.

The multi-stage AO process of multi-point influent water does not require additional carbon source, and according to the scale of sewage treatment of 30,3 m33/d, the sodium acetate solution with a concentration of 18% can be saved every day about 3 m3, and the annual operating cost can be saved by about 000.3 million yuan calculated by sodium acetate 1 944 yuan/m<>.

05 Conclusion

(1) The multi-point influent multi-stage AO process alternately arranges hypoxic and aerobic sections, so that nitrogen removal can be achieved without adding the internal circulation system and energy can be saved.

(2) The multi-point influent multi-stage AO process has obvious advantages in low-carbon and high-nitrogen sewage treatment in cold areas, which can optimize the allocation of carbon sources in sewage, so that carbon sources can be accurately used for nitrogen and phosphorus removal, and save carbon sources.

(3) Multi-point influent multi-stage AO process saves energy and reduces consumption, saves carbon sources, and is a technology worthy of wide promotion under the background of carbon peak and carbon neutrality in the new era.

Copyright 2020 - 2021 DESCSO. All Rights Reserved

Copyright 2020 - 2021 DESCSO. All Rights Reserved

添加专属客户服务

一对一回答您的问题

电话:025-86292120

Add dedicated customer service

Answer your questions one-on-one

Call:025-86292120

| Add a dedicated customer service |

|

|

Long press to identify and add |

Instrument manufacturer in the field of water quality analysis |

| Call:17521589555 | |

| Add a dedicated customer service |

|

|

Long press to identify and add |

Instrument manufacturer in the field of water quality analysis |

| Call:17521589555 | |